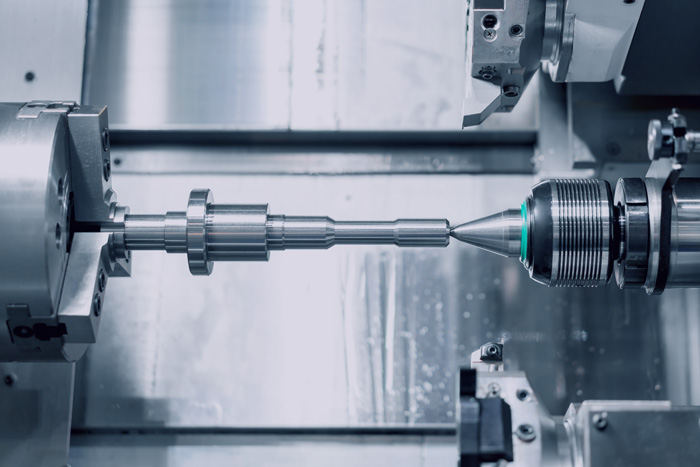

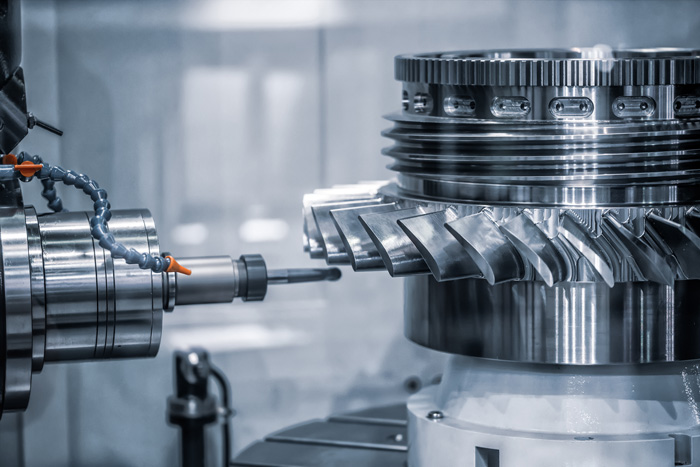

Hy-Speed machining has built the team, processes and facilities to handle projects from simple precision-machined components to the most complex. We are capable of milling and turning large and small precision-machined parts including ground and mid-air refueling gauges, pistons, castings, housings and valve bodies to name a few.

Scope of Core Machining Capabilities

Capable of holding tolerances to +/- .0001 (one ten-thousandth of an inch)

- Horizontal milling

- (X) 23.62” (Y) 17.71” (Z) 18.9”

- Vertical milling:

- (X) 40.9” (Y) 20.4” (Z) 23.6”

- Twin spindle:

- (X) 40.9” (Y) 20.4” (Z) 23.6”

- Horizontal Milling Pallet System:

- (X) 22” (Y) 25.2” (Z) 26”

Complimentary Capabilities

- Full-service supply chain management

- In house tooling and fixture design

- Dedicated customer service team providing a single point of contact once production starts.

Materials:

- Aluminum and aluminum alloys or machined castings

- Steel, 300 & 400 series Stainless steel

- Precipitation hardening stainless steels

- Titanium

- Brass (C360, yellow brass)

- Bronze (C954/C95400 aluminum bronze

- Aircraft alloys

- Exotic alloys (Nickel alloys, Inconel 600, Inconel 718, A286)

- Plastic